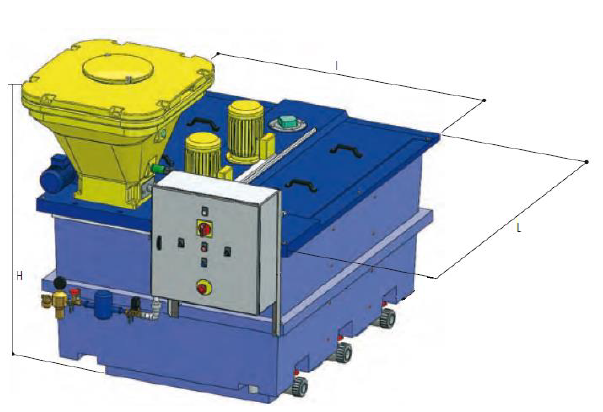

POLYMER DOSING SYSTEM Operating Principle The circulation of the polymer preparation is routed through the compartments, which are separated by baffles. In the preparation chamber, powder is uniformly mixed with water. The polypack is designed to allow a maturation time of 30 minutes to 120 minutes. The dosing chamber is fitted with three level switches. These level switches control the logic of the Automatic preparation cycle. The Logic of level switches are listed in the table. The Polypack is fitted with the powder screw feeder with a 60L hopper as standard. The powder screw feeder has a screw connected to a gear box and motor. The rate of powder feeding can be adjusted using a Variable frequency drive provided in the control panel. The water feed line is fitted with a pressure reducer, a control valve to control the water input rate, a flow meter to measure the water flow rate and a solenoid valve.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry