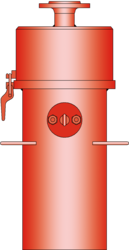

PROTEGO LA, LA/V, Air-Drying Device PROTEGO® air-drying device of types LA or LA/V is used when suction air must be dried for atmospheric venting of storage tanks where only little or no humidity is allowed to get into the tank or the stored product due to the process engineering. They are usually used in vertical or horizontal aboveground tanks which store non-flammable or flammable liquids, and which must not be vented with humid air for safe operation. The single device PROTEGO® LA mainly consists of the drying agent container (1). Its snap closing elements (2) connect it to the connection head (3) with flange connection according to DIN 2501 or to any other international standard. The bottom screen (4) and the protective strainer (5) are firmly welded into the drying agent container (1). The upper strainer cover (6) is loose. It can be removed easily to add or remove the drying agent. The connection head (3) contains the sealing plate (7) that closes the connection head opening when taking the drying agent container off. No humid air can be sucked in when changing the drying agent container. The upper part of the drying agent container (1) holds the integrated control cartridge (8). The control cartridge can be removed during operation. It shows if the drying agent contains humidity and has to be replaced for regeneration. Depending on the required flow rates or prescribed pressure losses the drying agent containers are delivered in two sizes – type I or type II. As parts of a modular system they are assembled into larger performance units. KC® drying pearls are used as the drying agent. The control cartridge (figure 1) is filled with special KC® indicator drying pearls. The required filling levels are specified in the relevant operating instructions. The air-drying device type LA/V is essentially similar to type LA. Additionally, it has a replaceable check valve (9) with protective strainer and valve pallet (10) integrated in the inlet connection. When no air is sucked in through the air-drying device the device is sealed and tight towards the atmosphere. So at high air humidity the drying agent in the lower area of the drying agent container cannot absorb moisture. The FEP diaphragm with air cushion sealing is used as valve pallet sealing up to pressure range II. From pressure range III, a lapped metallic sealing is used. Air-drying devices of types of LA or LA/V may be integrated into complete tank venting systems. If flammable liquids are stored in the tank, then flame arresters have to be installed in addition to the air-drying device and the pressure and vacuum relief valves. Depending on the operating conditions it is also possible to combine other vent valves with the integrated air-drying device. When the set vacuum is reached in the tank, the vacuum relief valve – for instance PROTEGO® type DZ/T or DV/ZU – connected to the air-drying device opens and the drying device LA sucks in atmospheric air while the drying agent (KC® drying pearls) absorbs the atmospheric humidity. The drying agent must be replaced and regenerated when depleted. Using a control cartridge, it is easily possible to determine whether the drying agent is saturated with humidity. Alternatively it is possible to pass the product vapour/air mixture through a suitable valve – e.g. PROTEGO® type DV/ZU into an exhaust line or exhaust system. Under pressure the vacuum side of the above valves remains closed and the product vapours cannot pass into the drying agent. In larger tanks it is recommended to also use combined pressure and vacuum relief valves e.g. PROTEGO® type VD/SV. This ensures that in an emergency (failure of air-drying device) atmospheric air can be sucked in directly through the vacuum side. Often direct atmospheric emergency venting is required yet it is neither possible nor necessary to size the air-drying device for the maximum volume flow calculated (pump flow-rate and thermal flow according to EN 14015 or API 2000). Maximum thermal flow occurs only rarely and it is therefore usually sufficient to size the air-drying device according to the pump flow-rate for emptying and a thermal flow portion of approximately 25%. Essentially, the air-drying device type PROTEGO® LA/V functions like type PROTEGO® LA. However, a check valve allows inbreathing only when the entire venting system – the tank and the drying container – is under vacuum at the set pressure of the check valve. The devices are designed for venting rates sufficient for the breathing of storage tanks. However, they do not replace any valves designed for emergency venting. The drying agent saturation can be easily monitored using a control cartridge. The drying agent can be regenerated. Drying agent and control drying pearls are not included in the PROTEGO® LA or LA/V and can optionally be ordered together with the device.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

PROTEGO LA, LA/V, Air-Drying Device PROTEGO® a...

2023-04-14T12:36:50

PROTEGO LA, LA/V, Air-Drying Device PROTEGO® air-drying device of types LA or LA/V is used when suction air must be dried for atmospheric venting of storage tanks where only little or no humidity is allowed to get into the tank or the stored product due to the process engineering. They are usually used in vertical or horizontal aboveground tanks which store non-flammable or flammable liquids, and which must not be vented with humid air for safe operation. The single device PROTEGO® LA mainly consists of the drying agent container (1). Its snap closing elements (2) connect it to the connection head (3) with flange connection according to DIN 2501 or to any other international standard. The bottom screen (4) and the protective strainer (5) are firmly welded into the drying agent container (1). The upper strainer cover (6) is loose. It can be removed easily to add or remove the drying agent. The connection head (3) contains the sealing plate (7) that closes the connection head opening when taking the drying agent container off. No humid air can be sucked in when changing the drying agent container. The upper part of the drying agent container (1) holds the integrated control cartridge (8). The control cartridge can be removed during operation. It shows if the drying agent contains humidity and has to be replaced for regeneration. Depending on the required flow rates or prescribed pressure losses the drying agent containers are delivered in two sizes – type I or type II. As parts of a modular system they are assembled into larger performance units. KC® drying pearls are used as the drying agent. The control cartridge (figure 1) is filled with special KC® indicator drying pearls. The required filling levels are specified in the relevant operating instructions. The air-drying device type LA/V is essentially similar to type LA. Additionally, it has a replaceable check valve (9) with protective strainer and valve pallet (10) integrated in the inlet connection. When no air is sucked in through the air-drying device the device is sealed and tight towards the atmosphere. So at high air humidity the drying agent in the lower area of the drying agent container cannot absorb moisture. The FEP diaphragm with air cushion sealing is used as valve pallet sealing up to pressure range II. From pressure range III, a lapped metallic sealing is used. Air-drying devices of types of LA or LA/V may be integrated into complete tank venting systems. If flammable liquids are stored in the tank, then flame arresters have to be installed in addition to the air-drying device and the pressure and vacuum relief valves. Depending on the operating conditions it is also possible to combine other vent valves with the integrated air-drying device. When the set vacuum is reached in the tank, the vacuum relief valve – for instance PROTEGO® type DZ/T or DV/ZU – connected to the air-drying device opens and the drying device LA sucks in atmospheric air while the drying agent (KC® drying pearls) absorbs the atmospheric humidity. The drying agent must be replaced and regenerated when depleted. Using a control cartridge, it is easily possible to determine whether the drying agent is saturated with humidity. Alternatively it is possible to pass the product vapour/air mixture through a suitable valve – e.g. PROTEGO® type DV/ZU into an exhaust line or exhaust system. Under pressure the vacuum side of the above valves remains closed and the product vapours cannot pass into the drying agent. In larger tanks it is recommended to also use combined pressure and vacuum relief valves e.g. PROTEGO® type VD/SV. This ensures that in an emergency (failure of air-drying device) atmospheric air can be sucked in directly through the vacuum side. Often direct atmospheric emergency venting is required yet it is neither possible nor necessary to size the air-drying device for the maximum volume flow calculated (pump flow-rate and thermal flow according to EN 14015 or API 2000). Maximum thermal flow occurs only rarely and it is therefore usually sufficient to size the air-drying device according to the pump flow-rate for emptying and a thermal flow portion of approximately 25%. Essentially, the air-drying device type PROTEGO® LA/V functions like type PROTEGO® LA. However, a check valve allows inbreathing only when the entire venting system – the tank and the drying container – is under vacuum at the set pressure of the check valve. The devices are designed for venting rates sufficient for the breathing of storage tanks. However, they do not replace any valves designed for emergency venting. The drying agent saturation can be easily monitored using a control cartridge. The drying agent can be regenerated. Drying agent and control drying pearls are not included in the PROTEGO® LA or LA/V and can optionally be ordered together with the device.

2023-04-14T12:36:50

Keywords

- API

- parts

- types

- figure

- little

- failure

- liquids

- vertical

- instance

- addition

- moisture

- DIN 2501

- emptying

- humid air

- two sizes

- PROTEGO LA

- set vacuum

- lower area

- atmosphere

- flow rates

- upper part

- suction air

- vacuum side

- inbreathing

- exhaust line

- regeneration

- valve pallet

- above valves

- larger tanks

- set pressure

- bottom screen

- single device

- PROTEGO® LA/V

- storage tanks

- sealing plate

- FEP diaphragm

- non-flammable

- modular system

- pump flow-rate

- exhaust system

- safe operation

- pressure range

- suitable valve

- flame arresters

- connection head

- product vapours

- atmospheric air

- pressure losses

- type PROTEGO® LA

- inlet connection

- drying container

- metallic sealing

- high air humidity

- combined pressure

- flange connection

- KC® drying pearls

- other vent valves

- PROTEGO® type DZ/T

- Air-drying devices

- maximum volume flow

- air cushion sealing

- atmospheric venting

- PROTEGO® type DV/ZU

- process engineering

- protective strainer

- PROTEGO® type VD/SV

- thermal flow portion

- Maximum thermal flow

- vacuum relief valves

- operating conditions

- atmospheric humidity

- upper strainer cover

- entire venting system

- control drying pearls

- snap closing elements

- air-drying device type

- drying agent saturation

- drying agent containers

- replaceable check valve

- required filling levels

- larger performance units

- product vapour/air mixture

- PROTEGO® air-drying device

- horizontal aboveground tanks

- integrated control cartridge

- other international standard

- complete tank venting systems

- relevant operating instructions

- special KC® indicator drying pearls

- direct atmospheric emergency venting

Submit Your Enquiry