Avoid the need for manual operations – Prevent dosing errors, operation stops.

Standardization of the obtained polymer – Concentration, maturation time, homogeneity.

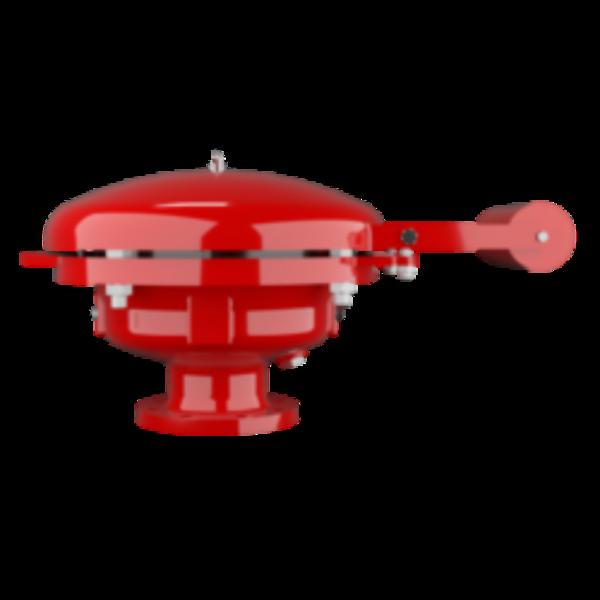

High efficiency mixers – Provide a low flow mixing for a homogeneous flocculant polymerisation without mechanical deterioration.

Optimised process – Visual access to the process and alarms, fieldbus distributed control (optional) provides informative and easy to access equipment and status application updates, controlled costs. Intelligent system that feeds the process when needed, regulated by an ultrasonic level switch.

Reliability and Robustness in Any Environment.

Option DUAL – Two-in-one solution, to prepare powder or liquid polymers. Ideal solution for wastewater plants located in areas subject to population changes, such as tourist areas, or locations subject to rainy season that have to adapt their process according to the population equivalent or the season.

Compact design – For easy transport and relocation.

Keywords

Any

need

costs

powder

alarms

process

locations

equipment

Robustness

relocation

homogeneity

informative

Reliability

Option DUAL

Environment

one solution

rainy season

Visual access

dosing errors

Concentration

tourist areas

Compact design

Ideal solution

easy transport

maturation time

Standardization

liquid polymers

low flow mixing

wastewater plants

manual operations

population changes

Intelligent system

population equivalent

High efficiency mixers

ultrasonic level switch

mechanical deterioration

status application updates

fieldbus distributed control

homogeneous flocculant polymerisation