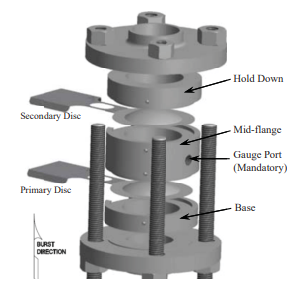

CONSIDERATIONS FOR THE USE OF DOUBLE DISC RUPTURE DISC ASSEMBLIES Double disc or “back-to-back” configurations of rupture disc devices consists of two rupture discs installed within a holder comprised of three separate components: 1) Base, 2) Mid-flange, and 3) Hold Down. See Illustration 1. Such configurations can be equipped with forward-acting, reverse-acting, or a combination of forward and reverse-acting discs for special process applications. Double disc arrangements can also be comprised of individual single rupture disc assemblies however these combinations may require specific testing and qualification to assure proper performance APPLICATIONS A common application for use of a double disc assembly is to isolate the upstream or “primary”rupture disc from sources of variable back pressure. For example, this condition can occur when multiple rupture disc assemblies, protecting multiple processes, discharge into a common header. If one rupture disc assembly bursts, the resulting discharge into the common header could subject the remaining rupture disc assemblies to a transient elevated back pressure condition. The downstream or “secondary” rupture disc is selected to withstand high back pressure events leaving the primary disc to burst within its specified rating. Another widely promoted application of double disc assemblies is within processes containing corrosive, toxic, and/or otherwise valuable media with the objective of reducing the possibility of leakage to the environment or loss of valuable products. This concept is accomplished by monitoring the pressure within the mid-flange volume to detect leakage through the primary disc possibly resulting from cyclic fatigue, Sulfide Stress Cracking, or other forms of deterioration and then subsequently replacing the rupture disc upon indication of leakage. It is critical in this application that the pressure in the mid-flange volume is actively and continuously monitored, and that replacement of the disc(s) is accomplished immediately upon detecting any increase in pressure.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

CONSIDERATIONS FOR THE USE OF DOUBLE DISC RUPTU...

2024-02-15T12:00:39

CONSIDERATIONS FOR THE USE OF DOUBLE DISC RUPTURE DISC ASSEMBLIES Double disc or “back-to-back” configurations of rupture disc devices consists of two rupture discs installed within a holder comprised of three separate components: 1) Base, 2) Mid-flange, and 3) Hold Down. See Illustration 1. Such configurations can be equipped with forward-acting, reverse-acting, or a combination of forward and reverse-acting discs for special process applications. Double disc arrangements can also be comprised of individual single rupture disc assemblies however these combinations may require specific testing and qualification to assure proper performance APPLICATIONS A common application for use of a double disc assembly is to isolate the upstream or “primary”rupture disc from sources of variable back pressure. For example, this condition can occur when multiple rupture disc assemblies, protecting multiple processes, discharge into a common header. If one rupture disc assembly bursts, the resulting discharge into the common header could subject the remaining rupture disc assemblies to a transient elevated back pressure condition. The downstream or “secondary” rupture disc is selected to withstand high back pressure events leaving the primary disc to burst within its specified rating. Another widely promoted application of double disc assemblies is within processes containing corrosive, toxic, and/or otherwise valuable media with the objective of reducing the possibility of leakage to the environment or loss of valuable products. This concept is accomplished by monitoring the pressure within the mid-flange volume to detect leakage through the primary disc possibly resulting from cyclic fatigue, Sulfide Stress Cracking, or other forms of deterioration and then subsequently replacing the rupture disc upon indication of leakage. It is critical in this application that the pressure in the mid-flange volume is actively and continuously monitored, and that replacement of the disc(s) is accomplished immediately upon detecting any increase in pressure.

2024-02-15T12:00:39

Keywords

- USE

- Base

- loss

- disc(s

- holder

- rating

- concept

- forward

- leakage

- sources

- example

- upstream

- increase

- objective

- indication

- downstream

- possibility

- environment

- other forms

- one rupture

- replacement

- combination

- primary disc

- Illustration

- disc devices

- common header

- qualification

- deterioration

- valuable media

- cyclic fatigue

- CONSIDERATIONS

- corrosive, toxic

- specific testing

- valuable products

- mid-flange volume

- two rupture discs

- pressure condition

- common application

- transient elevated

- proper performance

- multiple processes

- resulting discharge

- Such configurations

- reverse-acting discs

- primary”rupture disc

- double disc assembly

- disc assembly bursts

- double disc assemblies

- variable back pressure

- Sulfide Stress Cracking

- secondary” rupture disc

- Double disc arrangements

- three separate components

- high back pressure events

- special process applications

- multiple rupture disc assemblies

- remaining rupture disc assemblies

- DOUBLE DISC RUPTURE DISC ASSEMBLIES

- individual single rupture disc assemblies

Submit Your Enquiry