Flame quenching is a safety principle in which the flame front and hot combustion gases from an explosion are cooled and extinguished by passing through a heat-absorbing medium, preventing flame propagation beyond the protected area.

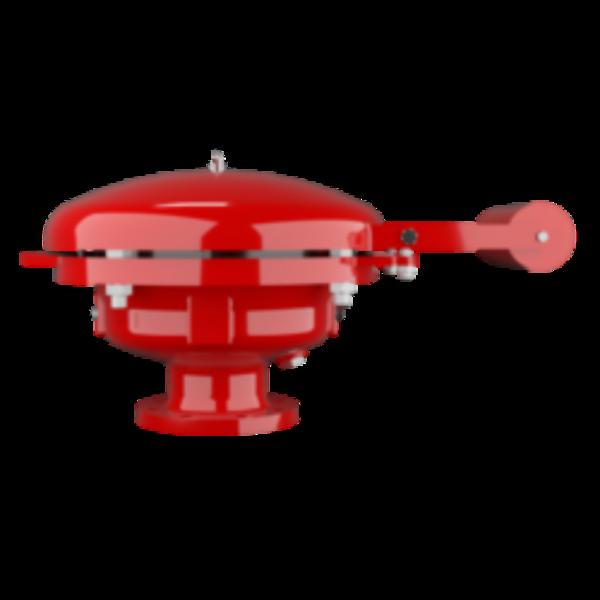

In industrial explosion protection, a flame quench device (also called a flameless vent) uses layers of metal mesh or similar materials to absorb heat and reduce the temperature of combustion gases below the ignition point, allowing pressure relief without releasing flames or sparks into the surrounding environment.

In simple terms:

Flame quenching allows an explosion to vent safely while stopping the flame from escaping.

Advantages:

Flameless explosion venting – prevents the release of flame, fireball, and hot combustion gases into the surrounding area

Safe indoor installation – allows explosion venting from equipment located inside buildings

Heat absorption technology – stainless-steel mesh absorbs combustion heat and quenches the flame front

Protection of personnel and equipment – minimizes secondary fires, injuries, and structural damage

High venting efficiency – large effective vent areas with low pressure drop

Suitable for ST1 and ST2 dusts – effective for non-metallic combustible dusts at reduced explosion pressures

Reduced explosion pressure (Pred) – typically effective at pressures ≤ 1.6 bar

No flame propagation – prevents flame transmission outside the protected process

Low maintenance – periodic inspection possible without full disassembly

Anti-static design – reduces dust accumulation and ignition risk

Extended service life – protective shields enhance durability and long-term performance

Keyword:

Flame quenching

Flameless explosion venting

Flame arrester

Explosion relief

Explosion vent

Dust explosion protection

Heat absorption

Stainless steel mesh

Flame suppression

Pressure relief

Combustible dust safety

ST1 / ST2 dust classification

Reduced explosion pressure (Pred)

Indoor explosion venting

ATEX compliant

NFPA 68 compliant

Fireball prevention

Secondary explosion prevention

Anti-static protection

Process safety