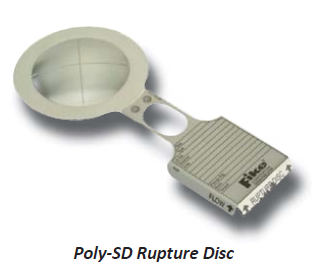

Poly-SD Rupture Disc

DESCRIPTION

The Fike Poly-SD rupture disc is a versatile disc. The Poly-SD can be used in liquid, vapor and two phase flow

and is available in a large variety of materials. The patented, smooth design of this rupture disc (free from

ledges or crevices preventing material buildup on the disc), also makes the Poly-SD ideal for polymerization

processes. In addition, the non-fragmenting Poly-SD rupture disc is well suited for pressure relief valve

isolation from process contaminants and corrosion.

FEATURES AND BENEFITS

Patented, smooth annular seating design helps prevent material build-up on disc

Created with a fail safe design which provides pressure relief at or below its rated burst pressure even if

damaged or installed upside down

Scoring on the downstream side controls the burst pressure and opening characteristics. The Poly-SD

series includes 3 different scoring configurations to optimize performance over a wide range of pressures

Can be used in liquid, vapor or multi-phase media applications

Can be operated as high as 90% of its rated burst pressure

Withstands full vacuum without a vacuum support in a wide range of pressures

Designed to be non-fragmenting

Available with a zero manufacturing range

Keywords

ledges

BENEFITS

FEATURES

crevices

addition

pressures

processes

materials

corrosion

isolation

wide range

full vacuum

DESCRIPTION

performance

liquid, vapor

large variety

vacuum support

two phase flow

versatile disc

burst pressure

downstream side

fail safe design

material buildup

material build-up

The Poly-SD series

process contaminants

pressure relief valve

patented, smooth design

opening characteristics

zero manufacturing range

The Fike Poly-SD rupture disc

multi-phase media applications

fragmenting Poly-SD rupture disc

3 different scoring configurations

Patented, smooth annular seating design