Protecting the Vessel: Explosion Venting

When a deflagration occurs, vent panels serve as the weak point of the enclosure and provide a pathway for expanding pressures and flames to escape. Preferably vent panels are installed on the silo roof to minimizing the impact on the fillable silo volume and preventing recoil forces causing structural damage during an explosion event.

Explosion venting is relatively inexpensive compared to other protection methods and requires little maintenance, but a large external exclusion zone must be present and post-explosion fires may take place inside the silo.

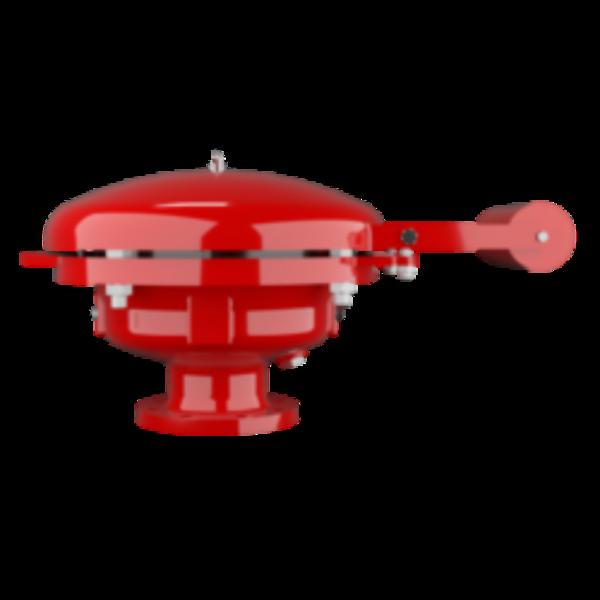

If a sufficient external exclusion zone is not available or when the silo is installed indoors flameless venting may provide a potential solution. A flameless venting device is placed on top of the explosion vent panel and contains a flame filter that extinguishes the explosion flames. An integrated dust retention screen prevents unburnt fuel from being discharged preventing secondary explosions to take place outside the silo.

Additional vent accessories such as weather covers are available to allow installation in even the harshest conditions. Hygienic explosion vents are also available for food storage silos where CIP cleaning is applied.

Keywords

top

post

place

impact

Vessel

pathway

pressures

enclosure

silo roof

weak point

vent panels

unburnt fuel

flame filter

installation

CIP cleaning

deflagration

recoil forces

weather covers

explosion event

explosion fires

explosion flames

structural damage

Explosion Venting

potential solution

little maintenance

food storage silos

harshest conditions

secondary explosions

fillable silo volume

explosion vent panel

flameless venting device

Hygienic explosion vents

other protection methods

Additional vent accessories

large external exclusion zone

integrated dust retention screen

sufficient external exclusion zone