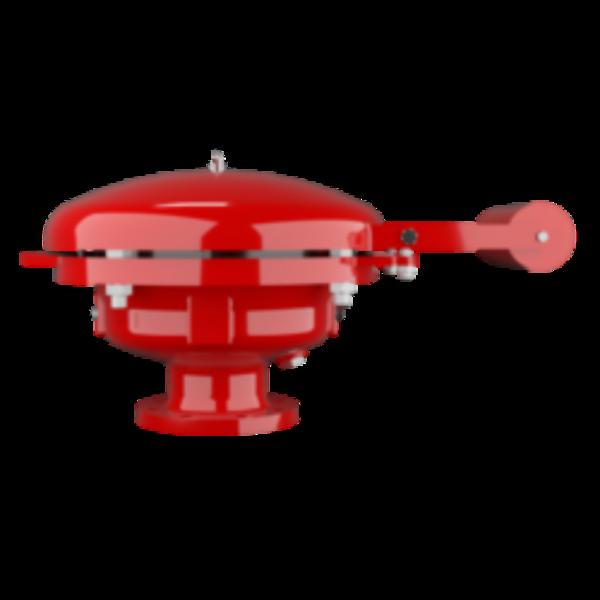

SV/E

Vacuum Relief Valve deflagration-proof

•10% technology for minimum pressure increase up to full lift.

• excellent tightness, resulting in lowest possible product losses and reduced environmental pollution.

• due to 10% technology, set pressure is close to opening pressure for optimum pressure maintenance in the system as compared to conventional 40% or 100% technology.

• high flow capacity

• valve pallet is guided inside the housing to protect against harsh weather conditions.

• can be used as a protective system in areas with potentially explosive atmospheres in accordance with ATEX

• FLAMEFILTER® provides protection against atmospheric deflagrations.

• integrated FLAMEFILTER® saves space and weight and reduces costs.

• FLAMEFILTER® is protected from clogging and sticky substances caused by product vapours.

• minimum pressure loss of the PROTEGO® flame arrester unit

• maintenance-friendly design

• modular design enables replacement of individual FLAMEFILTER® discs and valve pallet

• available in a special design with lifting device (for ships)

Keywords

SV/E

ATEX

ships

space

areas

costs

weight

housing

clogging

full lift

protection

accordance

replacement

valve pallet

set pressure

special design

10% technology

lifting device

modular design

product vapours

100% technology

protective system

sticky substances

high flow capacity

excellent tightness

explosive atmospheres

minimum pressure loss

environmental pollution

integrated FLAMEFILTER®

harsh weather conditions

atmospheric deflagrations

maintenance-friendly design

optimum pressure maintenance

PROTEGO® flame arrester unit

individual FLAMEFILTER® discs

lowest possible product losses

Vacuum Relief Valve deflagration-proof