Working principle of Flame Arresters

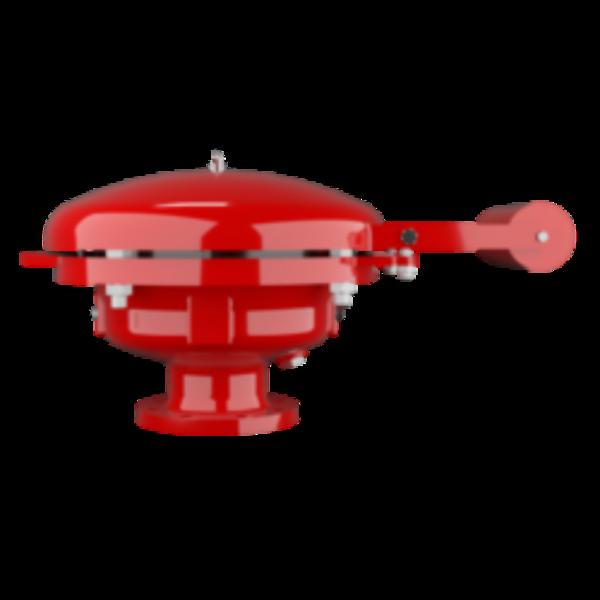

Flame Arresters (or ‘flame arrestors’) are designed to allow the flow of gases, liquids, etc. and to prevent flame transmission.

PROTEGO® Flame Arresters are composed of individual FLAMEFILTER® (flame arrester discs), spacers, and a casing. The FLAMEFILTER® is made of wound, corrugated metal strips. The principle of flame quenching in small gaps is applied in PROTEGO® end-of-line flame arresters and PROTEGO® in-line flame arresters.

When a mixture ignites in a gap between two walls, the flame spreads towards the non-combusted mixture. The expansion in volume of the combusted mixture pre-compresses the non-combusted mixture and accelerates the flame. By heat dissipation in the boundary layer “s”, transferring it to the large surface of the gap length compared to the gap width “D”, and by cooling down the product below its ignition temperature, the flame is extinguished.

The gap width and the gap length of the flame arrester disc determines its extinguishing ability. The narrower and longer the gap, the greater the extinguishing effectiveness. The wider and shorter the gap, the lower the pressure loss. Experiments can determine the optimum solution between the two conditions.

Keywords

line

flow

gases

volume

casing

spacers

liquids

product

expansion

two walls

gap width

small gaps

gap length

Experiments

pressure loss

large surface

two conditions

boundary layer

flame quenching

flame arrestors

heat dissipation

optimum solution

The FLAMEFILTER®

Working principle

combusted mixture

flame transmission

ignition temperature

flame arrester discs

extinguishing ability

corrugated metal strips

individual FLAMEFILTER®

PROTEGO® Flame Arresters

extinguishing effectiveness